Understanding UV DPSS Lasers: Technology, Applications, and Advancements

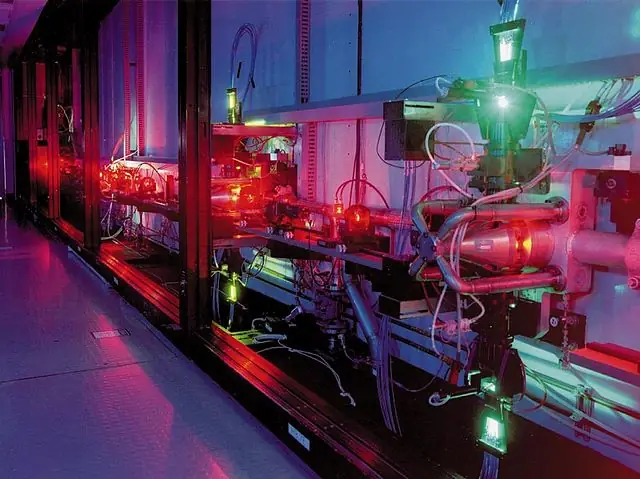

Since their inception in the 1960s, lasers have become an indispensable tool across various industries. One type of laser that has gained significant attention is the ultraviolet diode-pumped solid-state (UV DPSS) laser. This technology harnesses the power of ultraviolet light and combines it with the efficiency and compactness of DPSS systems, making it a versatile and powerful solution for a wide range of applications.

Fundamentals of DPSS Lasers

Diode-Pumped Solid-State (DPSS) UV Lasers: Components and Operation

A DPSS laser consists of a diode laser pump source that emits light, which is then absorbed by a solid-state gain medium. This process excites the electrons within the medium, generating a population inversion. The resonator cavity, consisting of mirrors, confines and reflects the light back and forth through the gain medium, amplifying it. As the light reaches a certain threshold, it exits the cavity, creating a laser beam.

Advantages of UV DPSS Lasers

Compared to other laser types, DPSS lasers offer several benefits. They are more energy-efficient, thanks to the direct coupling between the diode pump and gain medium. Their compact size makes them ideal for integration into various systems, while their longevity and excellent beam quality make them a reliable choice for high-precision applications.

Generating Ultraviolet Light in DPSS Lasers

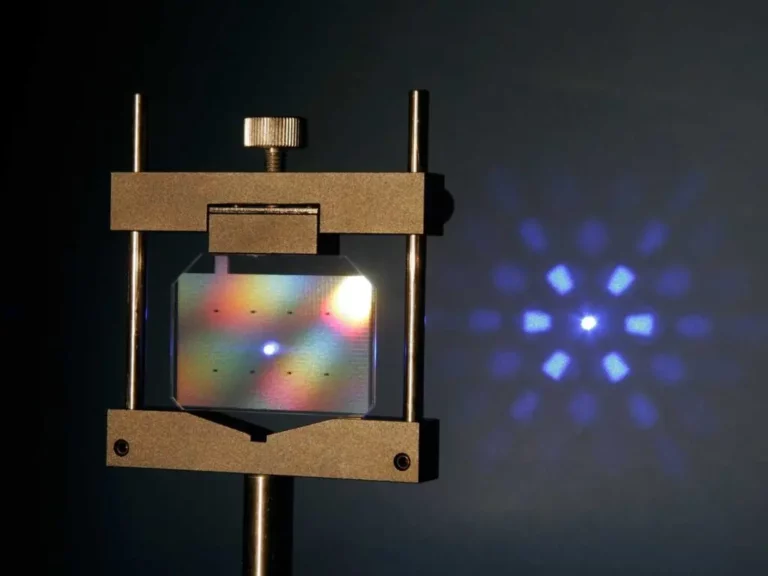

Nonlinear Optical Processes

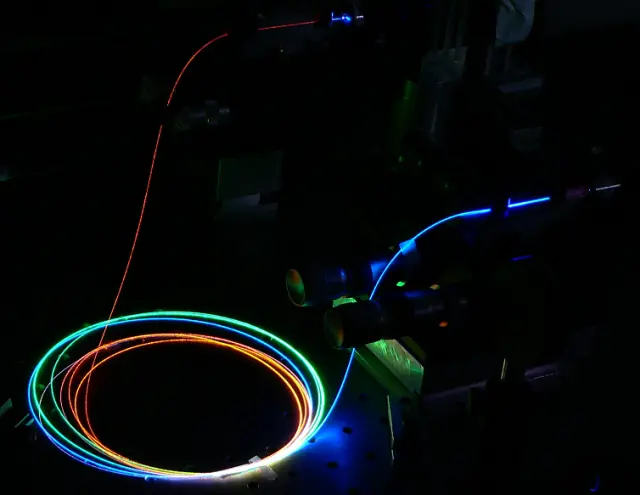

To generate ultraviolet light in DPSS lasers, nonlinear optical processes like second-, third-, and fourth-harmonic generation (SHG, THG, and FHG) are employed. These processes involve the conversion of lower-frequency input light into higher-frequency output light, effectively reducing the wavelength to the ultraviolet range.

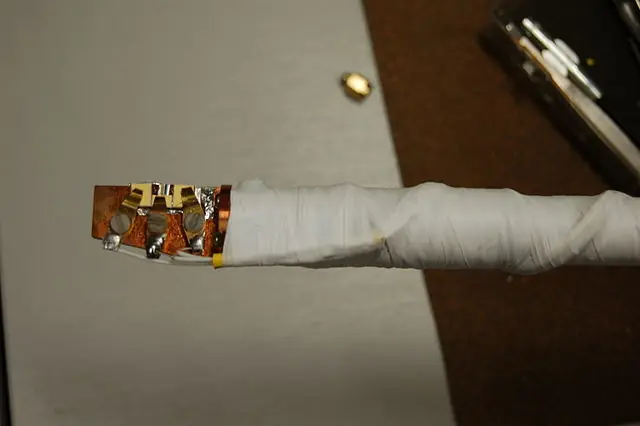

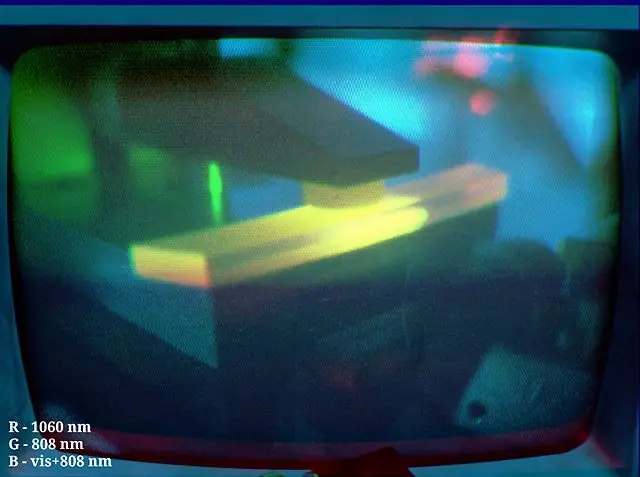

Choice of Solid-State Gain Media

The choice of solid-state gain media is crucial for UV generation. Common options include Nd:YAG (neodymium-doped yttrium aluminum garnet), Nd:YLF (neodymium-doped yttrium lithium fluoride), and Nd:YVO4 (neodymium-doped yttrium orthovanadate). Each of these materials has its unique properties, affecting the output wavelength range and tunability of the laser.

Applications of UV DPSS Lasers

Material Processing

UV DPSS lasers are widely used in material processing tasks, such as marking, engraving, cutting, and drilling. Their high precision and minimal thermal damage make them ideal for processing sensitive materials, including plastics, glass, and semiconductors.

Biomedical Applications

In the biomedical field, UV DPSS lasers have found applications in ophthalmic surgery, dermatology treatments, and fluorescence microscopy. Their precision and ability to deliver controlled energy doses make them suitable for delicate procedures without causing excessive collateral damage to surrounding tissues.

Semiconductor Industry

Photolithography and inspection processes in the semiconductor industry also benefit from UV DPSS lasers. Their high-resolution capabilities and tunable wavelengths enable precise patterning and quality control, essential for the production of advanced microelectronics.

Scientific Research

Researchers use UV DPSS lasers for spectroscopy, particle manipulation, and cold atom research. Their versatility, reliability, and tunability make them an invaluable tool in various scientific investigations.

Recent Advances and Future Prospects

Improved Efficiency and Power Scaling

Continuous advancements in UV DPSS lasers have led to improved efficiency and power scaling. These improvements enable the development of more powerful and versatile laser systems suitable for a broader range of applications.

Miniaturization and Integration

The miniaturization of UV DPSS lasers has paved the way for their integration into portable devices. This development has the potential to revolutionize industries that require compact and mobile laser solutions.

Wider Wavelength Tunability

Researchers are exploring new materials and techniques to achieve wider wavelength tunability in UV DPSS lasers. As tunability expands, these lasers will become even more versatile and adaptable to a variety of applications, further broadening their impact across industries.

New Materials and Techniques for UV DPSS Laser Generation

The development of novel materials and innovative methods for generating ultraviolet light in DPSS lasers is an ongoing area of research. Breakthroughs in this field have the potential to enhance the efficiency, power, and wavelength range of UV DPSS lasers, making them more practical and effective tools for a diverse array of tasks.

Conclusion

The UV DPSS laser technology has transformed the way we harness and utilize ultraviolet light across numerous applications. Its energy efficiency, compact size, and excellent beam quality have made it a preferred choice in material processing, biomedical applications, the semiconductor industry, and scientific research. As advancements continue to be made in efficiency, miniaturization, wavelength tunability, and UV generation, we can expect even more innovative and impactful uses for these versatile lasers in the future.