Yttrium-Aluminum-Garnet Crystal-Derived Silica Fiber Laser Boasts Over 60% Optical-to-optical Conversion Efficiency

A recent study highlights a significant breakthrough in the field of fiber laser technology, which promises to pave the way for next-generation applications in various sectors such as industrial processing, bioanalytics, metrology, and precision detection. Researchers have successfully fabricated a silica optical fiber derived from yttrium-aluminum-garnet (YAG) crystals, demonstrating superior output power and optical-to-optical conversion efficiency in linearly polarized single-frequency fiber lasers (LPSFFLs). This innovative approach, offering the highest performance rates observed thus far among similar fiber lasers, ushers in new opportunities for the development of advanced tools and techniques in scientific and industrial research.

Background and Relevance

Fiber lasers, which function by transmitting a laser beam through an optical fiber, are a vital component of many research, industrial, and technological applications. Over the years, various fiber laser types and configurations have been explored, with linearly polarized single-frequency fiber lasers (LPSFFLs) emerging as a highly efficient and reliable solution for a multitude of purposes. These versatile LPSFFLs are commonly used for industrial processing, metrology, bioanalytic systems, and precision detection in areas such as sensor and instrumentation design and manufacturing.

Efficiency and output power are two critical parameters that determine the performance and overall usability of fiber lasers. Existing silica gain fiber-based LPSFFLs, despite being widely used, exhibit substantial limitations in terms of optical-to-optical conversion efficiency and output power. In recent years, researchers have been striving to overcome these constraints without compromising the inherent advantages of LPSFFLs.

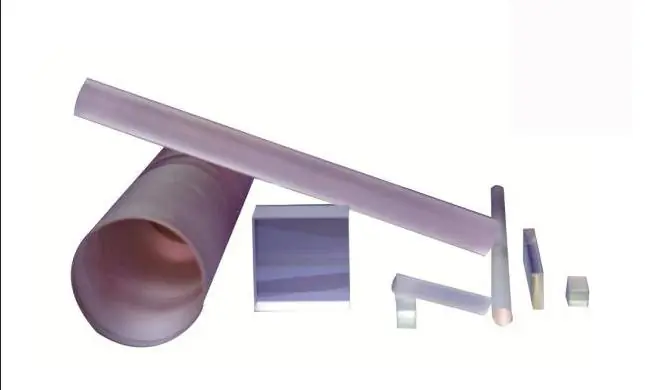

Yttrium-Aluminum-Garnet (YAG) crystals have been gaining increasing attention for their potential applications in optical fiber technology, due to their inherent ability to achieve high rare-earth ion doping concentrations. By incorporating these crystals into silica fibers, scientists have been aiming to enhance the performance of LPSFFLs while opening up exciting new opportunities in scientific research and industry applications.

Methods and Approach

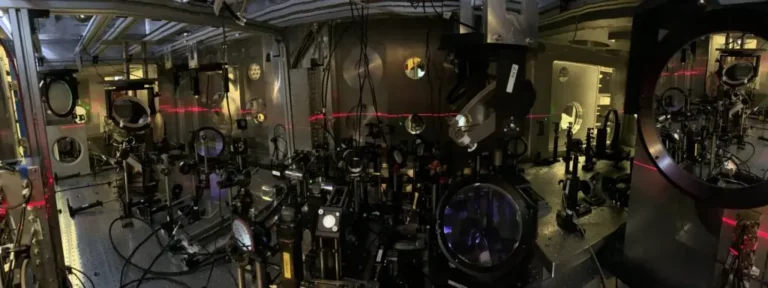

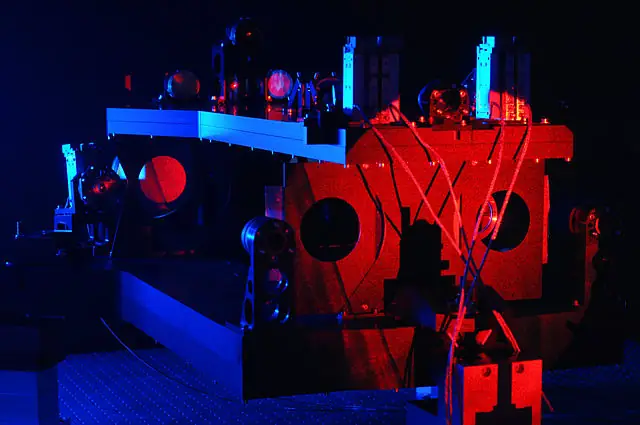

Building on this understanding, the researchers devised an innovative method to fabricate a new type of silica optical fiber derived from YAG crystals. The resultant yttrium-aluminum-garnet crystal-derived silica fiber (YCDSF) exhibited unprecedented performance characteristics that improve upon those found in conventional LPSFFLs.

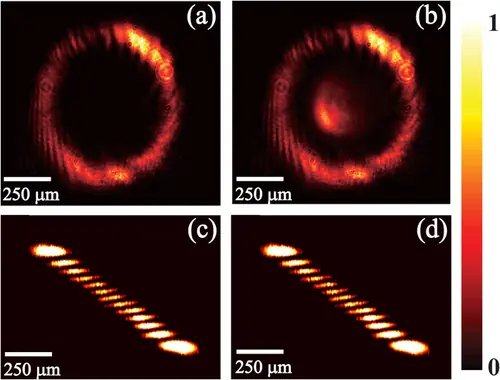

To achieve this, the researchers synthesized a YAG crystal doped with 6.57 wt.% ytterbium (Yb), a key ingredient necessary for increasing the gain of the fiber. They then constructed a 0.8-cm-long YCDSF by using preform fabrication processes that allowed them to optimize the fiber’s doping concentration and preserve its beneficial properties.

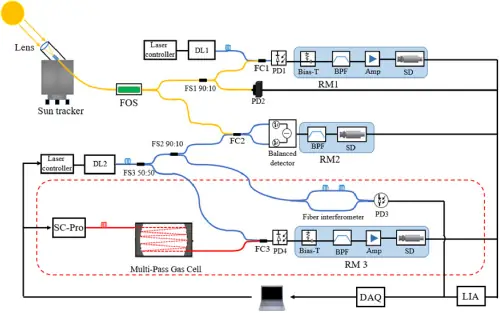

Following the fabrication of the YCDSF, the researchers set out to demonstrate its efficacy in a LPSFFL setup. Through a series of experiments, they conducted a comprehensive evaluation of the YCDSF-based laser’s performance in terms of gain coefficient, output power, optical-to-optical conversion efficiency, relative intensity noise, and polarization extinction ratio. The study design also involved comparing these findings against previously reported results for similar fiber lasers, in order to assess the overall effectiveness of the YAG crystal-derived approach.

Noteworthy Results and Insights

One remarkable outcome of the study is the significant enhancement of performance metrics, which positions the YCDSF-based LPSFFL ahead of its counterparts in terms of capability and potential applications. The YCDSF exhibited a gain coefficient of 6.0 dB/cm at 1030 nm, representing an important benchmark that surpasses the levels achieved by other fiber laser types.

Furthermore, the YCDSF-based LPSFFL achieved an impressive output power of over 350 mW, along with an optical-to-optical conversion efficiency as high as 63.0%. These values, among the highest ever reported for similar fiber lasers, indicate a marked improvement in desired characteristics, essentially making the YCDSF-based LPSFFL a frontrunner in the fiber laser technology landscape.

Additionally, the researchers observed a relative intensity noise of less than -143.5 dB/Hz, alongside a polarization extinction ratio of greater than 21 dB. These parameters further underline the superior performance of the YCDSF-based LPSFFL, showcasing its extraordinary stability and reliability in various applications.

Impact and Potential Benefits

The breakthrough demonstrated in this study has far-reaching implications for multiple industries and scientific domains that rely on fiber lasers as a fundamental tool. By significantly increasing the output power and optical-to-optical conversion efficiency in LPSFFLs, the novel approach has effectively expanded their potential applications and overall versatility.

In the realm of industrial processing, the YCDSF-based LPSFFL can enable faster and more accurate machining, cutting, and welding tasks, leading to increased productivity and higher quality results. Similarly, bioanalytic systems can leverage the enhanced capabilities of the YCDSF-based laser to achieve greater precision and sensitivity in detecting biomolecules or quantifying biochemical reactions.

Metrology, which relies on fiber lasers to measure and analyze complex physical properties and phenomena, can benefit from the improved efficiency and output power of the YCDSF-based LPSFFL. This can lead to more accurate measurements and discoveries, further advancing our understanding of the universe.

Lastly, precision detection systems and sensors can take advantage of the YCDSF-based laser’s unprecedented performance to gain more precise and reliable data, contributing to the development of cutting-edge applications across scientific and industrial domains.

Drawbacks, Limitations, and Future Research

Despite the enormous potential and impressive achievements showcased in this study, it is crucial to recognize that several areas require further examination and refinement before the YCDSF-based LPSFFL can be fully integrated into real-world applications.

One possible limitation, as noted in the paper, lies in the fabrication process itself, as the current method may be labor-intensive or challenging to scale, which would hinder the wide-scale adoption of YCDSF-based LPSFFLs. To overcome this, researchers can explore more advanced, streamlined approaches to fiber fabrication, with the ultimate goal of making YCDSF-based lasers accessible and affordable for diverse audiences.

Additionally, the investigation of other rare earth elements or crystal compositions may lead to further improvements in the properties and performances of this innovative fiber laser variant. A thorough understanding of the underlying mechanisms at play, as well as their interactions with other new or existing substances, could open doors for further advancements in fiber laser technology.

This study presents a major step forward in the development of next-generation fiber lasers that offer unparalleled efficiency and output power, while also posing fresh challenges and questions for the scientific community. Continued exploration and experimentation in this field, coupled with growing research efforts and interdisciplinary collaborations, will undoubtedly contribute to the evolution of innovative applications and groundbreaking discoveries in the realm of fiber laser technology.