The Lotus Effect Meets Laser Science: Pneumatically Tunable Ionic Liquid Microlasers

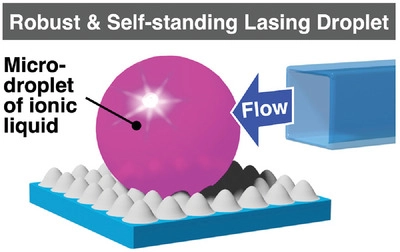

A new type of laser has been developed by scientists from the Tsukuba Research Center for Energy Materials Science at the University of Tsukuba that is both robust in air and tunable by airflow. This is a significant advancement from existing “droplet lasers” that have been unable to operate in normal settings as they require an enclosed container to prevent evaporation. The latest development, reported by scientists from the Tsukuba Research Center for Energy Materials Science at the University of Tsukuba, demonstrates a simple method for producing ionic liquid microdroplets that work as flexible, long-lasting and pneumatically tunable lasers. This breakthrough opens up new possibilities for lasers that can be used in everyday life.

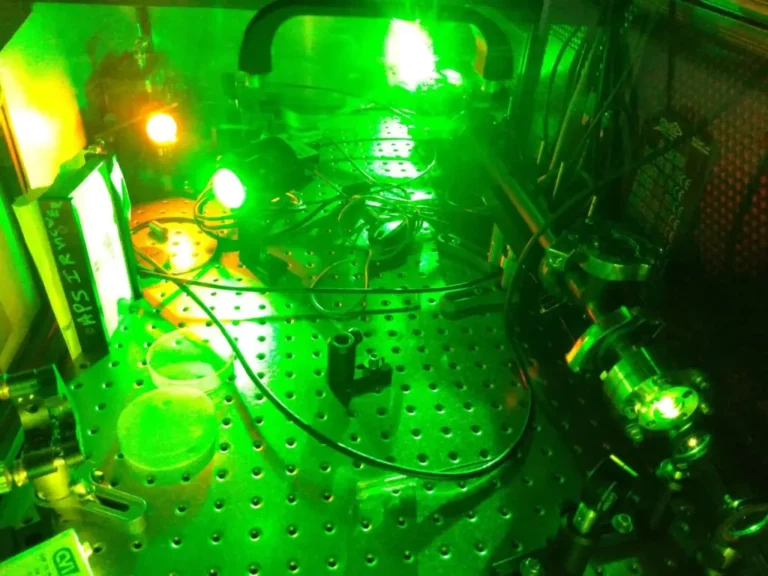

The new laser droplets are created by using an ionic liquid called 1-ethyl-3-methylimidazolium tetrafluoroborate (EMIBF4) mixed with a dye that allows it to become a laser. The choice of this particular liquid is due to its slow evaporation rate and relatively large surface tension. A quartz substrate is coated with tiny fluorinated silica nanoparticles to make the surface repel liquids. When the EMIBF4 is deposited on it from a pipette, the tiny droplets remain almost completely spherical. The researchers showed that the droplet could remain stable for at least 30 days.

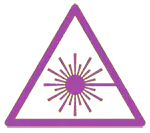

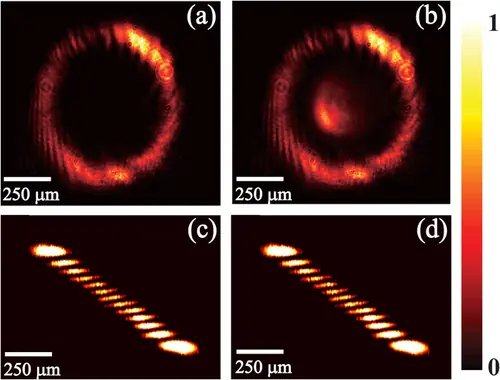

The stability and spherical shape of the droplets allow them to maintain an optical resonance when excited with a laser pumping source. The ability of the droplets to remain stable means that they can be used in a wide range of applications, including being used as a very sensitive humidity sensor or airflow detector. Additionally, blowing nitrogen gas can shift the laser peaks in the range of 645 to 662 nm by slightly deforming the droplet shapes, making them “reversibly tunable by gas convections.” This is a significant advancement, as this is the first liquid laser oscillator that can be tuned in this way.

In order to manufacture the laser droplets on a larger scale, the researchers employed a commercial inkjet printing apparatus equipped with a printer head that could work with a viscous liquid. The printed arrays of laser droplets worked without the need for further treatment, demonstrating that the production process is highly scalable and easy to perform. This breakthrough has the potential to lead to new airflow detectors or less expensive fiber-optics communications.

The findings of this research have been published in the journal Laser & Photonics Reviews, indicating that the development of this new type of laser could have far-reaching implications for the future of optical communication and sensing technologies. The researchers believe that the ease of production and scalability of the laser droplets make them ideal for use in the manufacturing of inexpensive sensor or optical communication devices. The potential applications of this new technology are vast, and it will be exciting to see how it develops in the coming years.