What is Multiphoton Lithography?

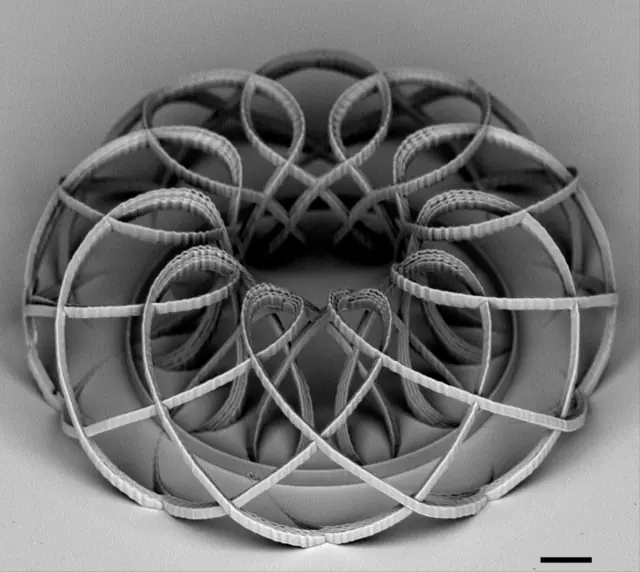

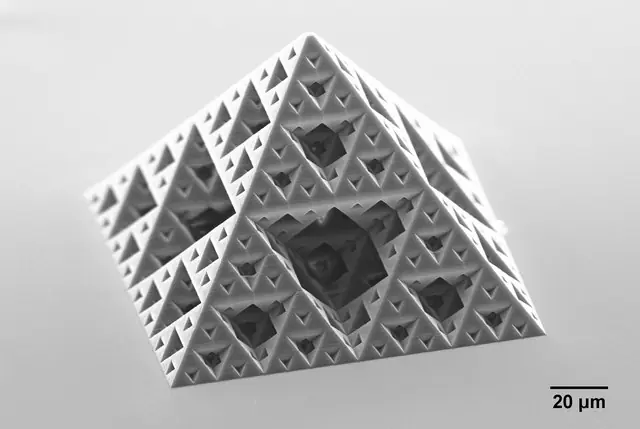

Multiphoton lithography, also known as two-photon lithography, is a cutting-edge technology used in the field of microfabrication. This technique is used to create intricate three-dimensional structures, such as those found in microelectronics, biotechnology, and photonics. In this article, we will explore the fundamentals of multiphoton lithography, including its history, principles, and applications.

The history of multiphoton lithography can be traced back to the late 1980s, when scientists first discovered that two-photon absorption could be used to create 3D structures. This discovery was made by accident when scientists were experimenting with laser-induced fluorescence in biological samples. They observed that when a laser was focused on a sample, it created a two-photon absorption effect that led to the formation of small three-dimensional structures. This observation led to the development of multiphoton lithography as a technique for creating micro- and nano-structures.

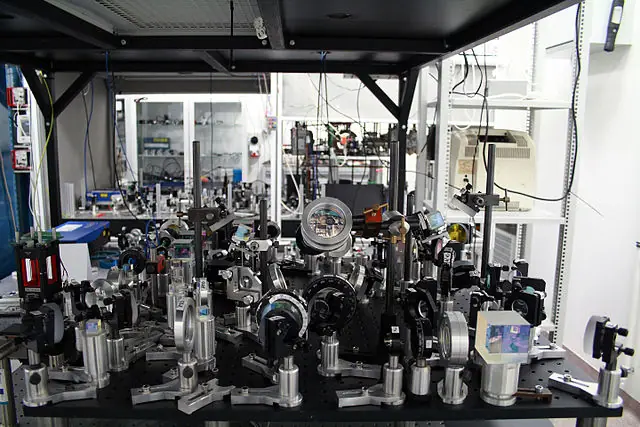

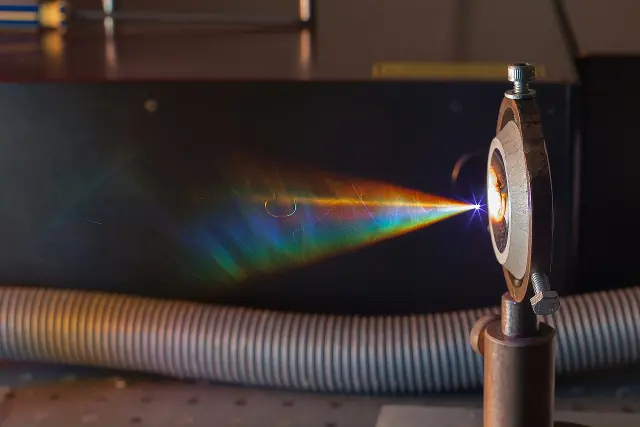

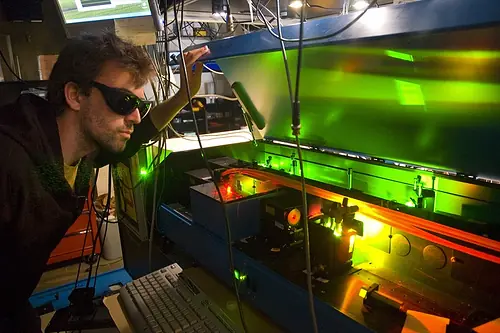

The principles of multiphoton lithography are based on the phenomenon of two-photon absorption, which occurs when two photons are absorbed simultaneously by a material. This process is highly localized and only occurs in the focal point of a laser beam. When a laser beam is focused on a photosensitive material, such as a photoresist, the material is exposed to the laser only in the focal point. The material in the focal point absorbs the laser energy and undergoes a chemical reaction that leads to the formation of a micro- or nano-structure.

The key advantage of multiphoton lithography is its ability to create 3D structures with high resolution and precision. This is because the process is highly localized, and the size and shape of the structures are determined by the laser beam’s focal point. Additionally, multiphoton lithography is a non-contact process, which means that it does not damage the material being processed. This makes it ideal for creating structures in delicate materials, such as biological samples.

Multiphoton lithography has a wide range of applications in various fields. In microelectronics, it is used to create micro- and nano-scale structures, such as transistors and integrated circuits. In biotechnology, it is used to create 3D structures for tissue engineering, drug delivery, and biosensors. In photonics, it is used to create micro-optical components, such as waveguides and micro-lenses.

In conclusion, multiphoton lithography is a cutting-edge technology that has revolutionized the field of microfabrication. Its ability to create 3D structures with high resolution and precision has made it a valuable tool in various fields, such as microelectronics, biotechnology, and photonics. As the demand for micro- and nano-scale structures continues to grow, multiphoton lithography will play an increasingly important role in the development of new technologies.