CO2 Lasers

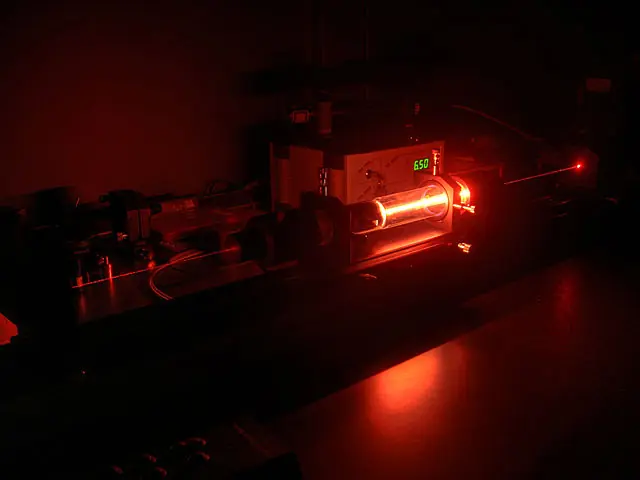

A CO2 laser is a gas laser that uses a carbon dioxide gas mixture. The gas mixture is typically made up of about 10% carbon dioxide, 10% nitrogen, and 80% helium. CO2 lasers are the most commonly used type of laser in industry and are used in a variety of applications including cutting, welding, and engraving.

CO2 lasers were first developed in the early 1960s by two Bell Laboratories scientists, Robert Swanson and Gordon Gould. Swanson and Gould were working on a project to develop a laser that could be used for long-distance communication. They discovered that a CO2 gas mixture could be used to create a laser beam that was intense enough to be used for communication.

CO2 lasers quickly became popular in industry due to their versatility. They can be used for a variety of applications including cutting, welding, and engraving. CO2 lasers are also used in medicine for surgeries and cosmetic procedures.

The first CO2 laser was a continuous wave (CW) laser. This type of laser produces a beam that is continuous, meaning that the beam is always on. CW CO2 lasers are still used in some applications, but the majority of CO2 lasers now used are pulsed lasers.

Pulsed CO2 lasers produce a beam that is turned on and off very quickly. The duration of the pulse can be very short, on the order of a nanosecond. The advantage of pulsed CO2 lasers is that they can produce very high powers. The peak power of a pulsed CO2 laser can be 100 times higher than the average power of a CW CO2 laser.

The high power of pulsed CO2 lasers makes them well suited for cutting and welding applications. When the laser beam is pulsed on and off very quickly, it can melt and vaporize materials. This process is called laser cutting and is used to cut through metals, plastics, and other materials.

Pulsed CO2 lasers are also used for welding. When the laser beam is pulsed on and off, it can heat up and melt two pieces of metal together. This process is called laser welding and is used to weld together metals, plastics, and other materials.

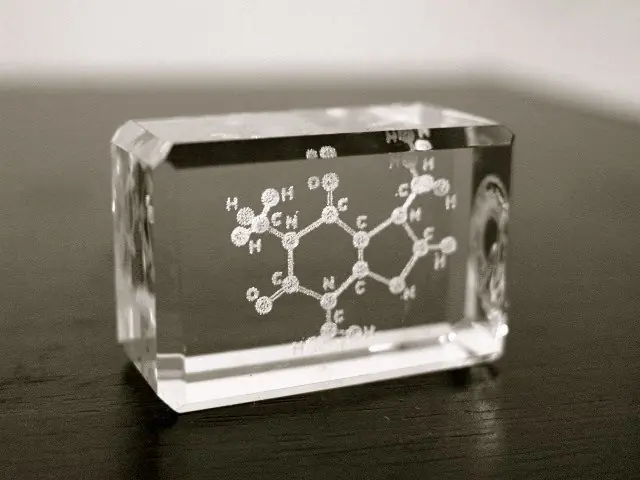

CO2 lasers are also used for engraving. When the laser beam is directed at a material, it can remove material from the surface. This process is called laser engraving and is used to create designs on metals, plastics, and other materials.

CO2 lasers have a number of advantages over other types of lasers. They are relatively inexpensive to manufacture and their power can be easily adjusted. CO2 lasers can also be used for a variety of applications, making them very versatile.