What is laser cleaning and what is it used for?

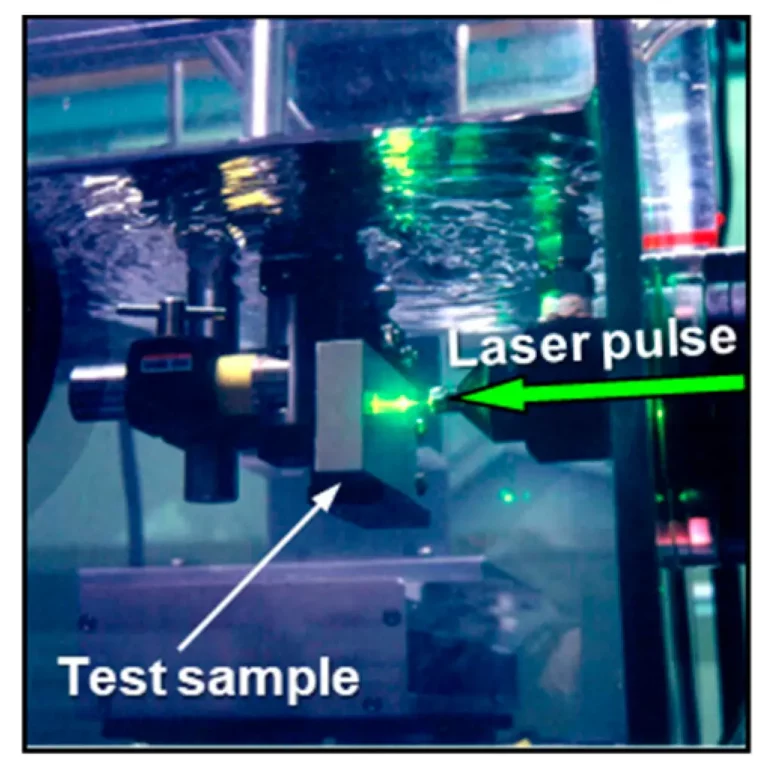

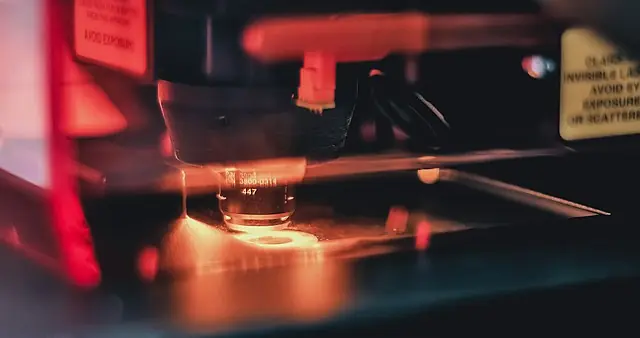

Laser cleaning is a process that utilizes a high-energy beam of light to remove contaminants, such as dirt, grime, rust, and paint, from a surface without causing any damage to the underlying material. The laser beam is focused onto the surface to be cleaned, and the energy from the beam is absorbed by the contaminants, causing them to vaporize or disintegrate. The resulting vapor or dust is then removed from the surface using a vacuum or other collection system.

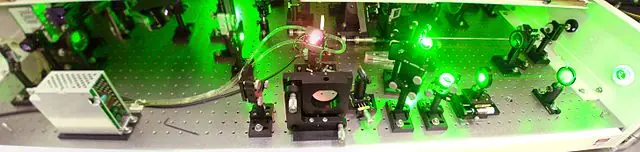

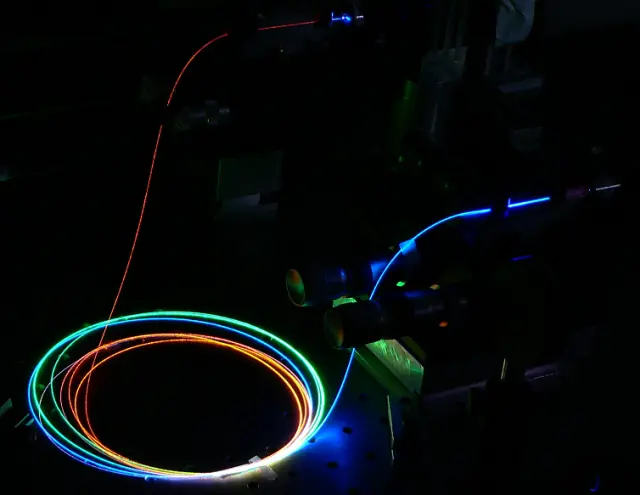

There are several different types of lasers that can be used for cleaning, including CO2 lasers, Nd:YAG lasers, and fiber lasers. CO2 lasers are the most commonly used for cleaning due to their high absorption rate in organic materials and their ability to penetrate deep into the surface. Nd:YAG lasers, on the other hand, are more suitable for removing hard and thick coatings, such as paint or rust, as they produce a higher peak power and can operate at higher pulse repetition rates. Fiber lasers are also increasingly being used for cleaning due to their high beam quality and ability to operate at wavelengths that are not absorbed by most materials.

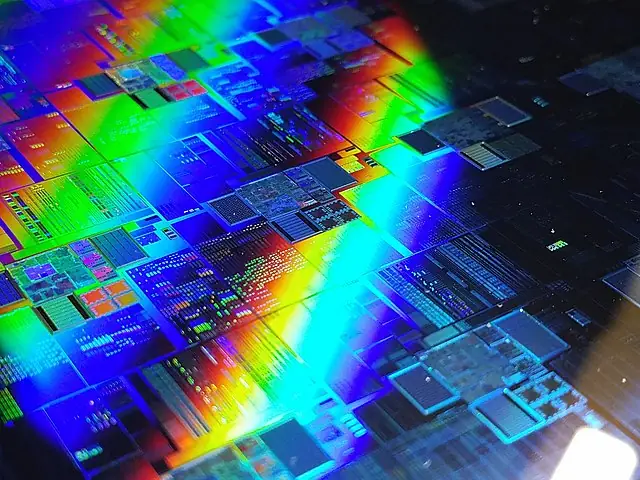

Laser cleaning has a number of advantages over traditional cleaning methods, such as sandblasting or chemical cleaning. It is a highly precise process, as the laser beam can be focused onto a small area or spot, allowing for the removal of contaminants from specific areas without affecting the surrounding material. It is also a non-contact process, meaning that it does not cause any mechanical stress or damage to the surface being cleaned. This makes it particularly useful for cleaning delicate or sensitive surfaces, such as electronic components or artwork.

One of the main applications of laser cleaning is in the industrial and manufacturing sector, where it is used to remove contaminants from machinery and equipment, such as welds, gears, and bearings. It is also commonly used in the restoration and conservation of historical artifacts, as it allows for the removal of dirt and grime without damaging the surface or underlying material. Laser cleaning is also increasingly being used in the automotive and aerospace industries, as well as in the power generation and oil and gas industries.

In summary, laser cleaning is a highly precise and non-destructive method for removing contaminants from surfaces without causing any damage. It is widely used in a variety of industries, including manufacturing, restoration, and conservation, and has a number of advantages over traditional cleaning methods.