How Lasers Are Shaping the Future of Custom Dentistry

Lasers are increasingly being used in dentistry as technology advances. Lasers can be used for a variety of dental procedures, including teeth whitening, cavity detection, and even tooth removal.

One of the main advantages of using lasers in dentistry is that they can be very precise. This means that there is less chance of damage to surrounding tissues when lasers are used for dental procedures. Lasers can also be used to target specific areas in the mouth, which helps to minimize discomfort and speed up healing times.

Another advantage of using lasers in dentistry is that they can help to reduce the spread of infection. This is because lasers can kill bacteria and viruses on contact. This means that patients who undergo laser dental procedures are less likely to develop infections afterwards.

Finally, lasers can also be used to improve the overall appearance of teeth. For example, laser teeth whitening can make teeth several shades brighter in just one session. In addition, laser-assisted bonding can help to repair chips or cracks in teeth.

Overall, lasers are shaping the future of custom dentistry by making procedures more precise, reducing the spread of infection, and improving the overall appearance of teeth.

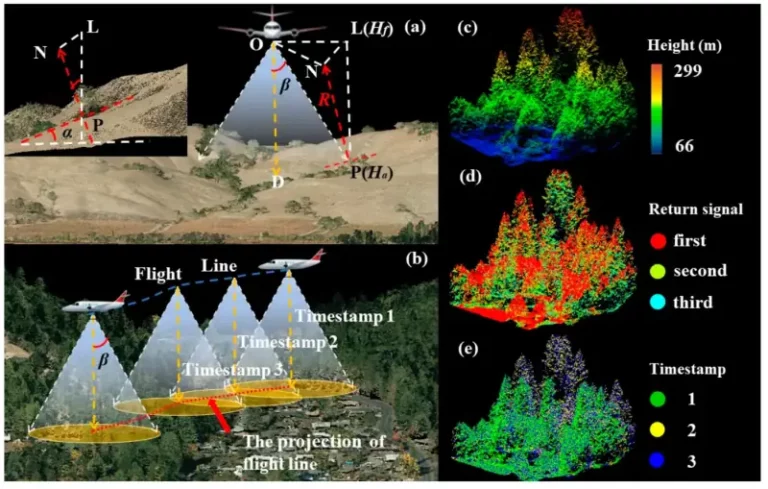

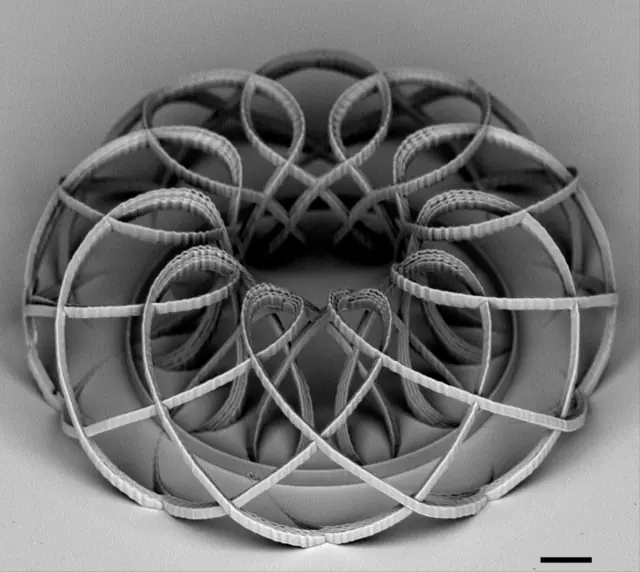

Direct metal laser sintering (DMLS) is a 3D printing technology that uses a high-power laser to fuse together small particles of metal powder. The resulting object is typically about 80% denser than the original powder.

DMLS can be used to create complex shapes that would be difficult or impossible to produce using traditional manufacturing methods. This makes it an ideal technology for creating custom dental implants and other prosthetics.

In addition, DMLS can be used to create prototypes or short-run production parts without the need for expensive tooling. This makes it an ideal technology for small dental labs or individual dentists who want to offer their patients custom-made dental products.

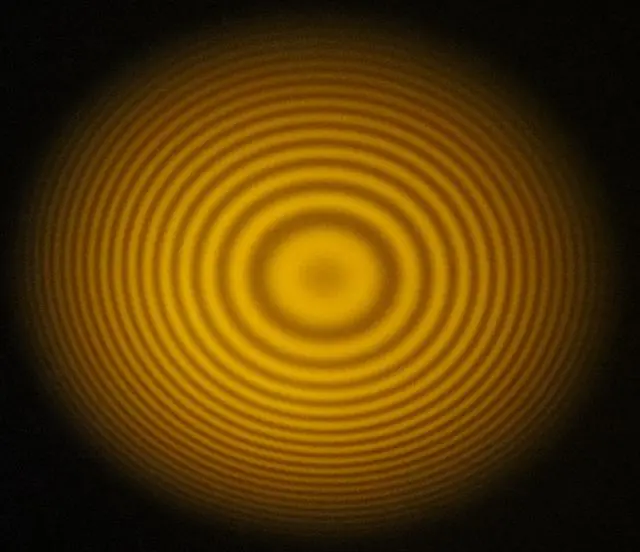

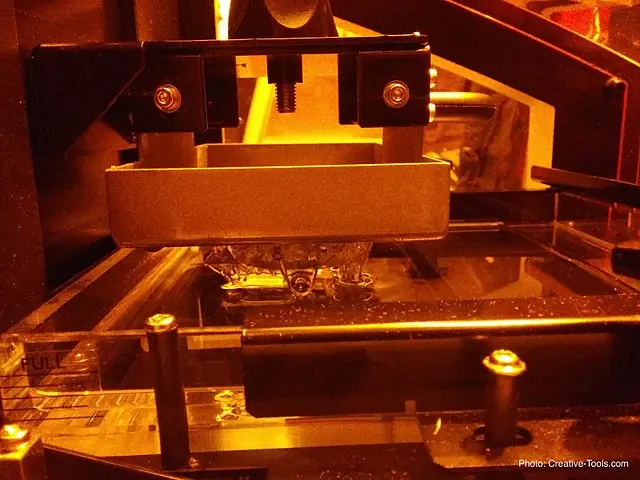

Stereolithography (SLA) is a 3D printing technology that uses a laser to cure photosensitive resin into solid objects. SLA printers are typically very accurate, with layer thicknesses as low as 0.025mm.

SLA can be used to create highly detailed dental models and prototypes. This makes it an ideal technology for creating custom dental implants and other prosthetics. In addition, SLA can be used to create short-run production parts without the need for expensive tooling.

SLA is also well suited for creating clear dental appliances such as retainers and night guards. The high accuracy of SLA allows for a snug fit that is comfortable for the patient and minimizes the risk of irritation or ulceration.