What is a fiber coupled laser?

Fiber coupled lasers are a significant technological advancement that has revolutionized many industries. They are used in applications such as telecommunications, medical research, and material processing. The coupling process enables efficient power transmission and precision beam delivery. This article will explore the science behind fiber coupled lasers, their applications, challenges, trends, and future potential.

Principles of Fiber Coupled Lasers

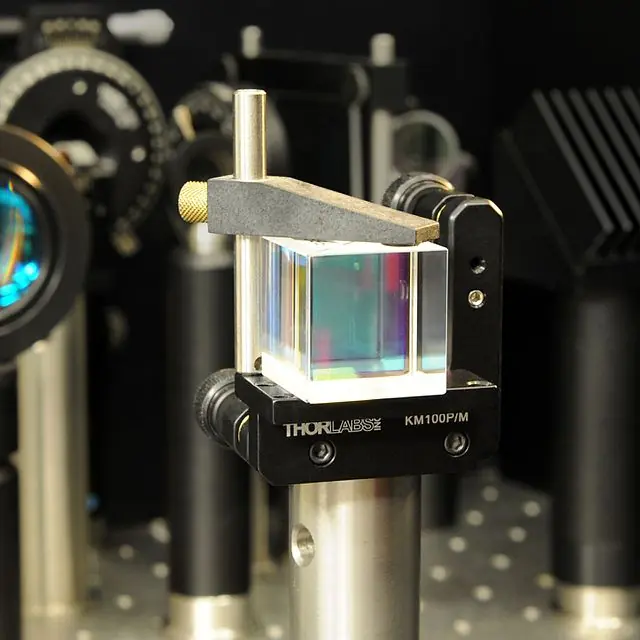

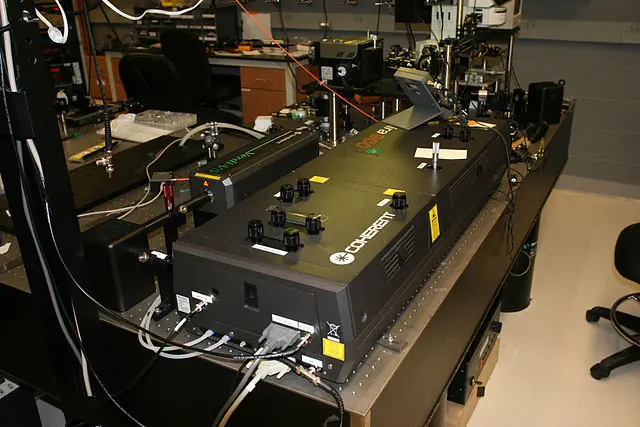

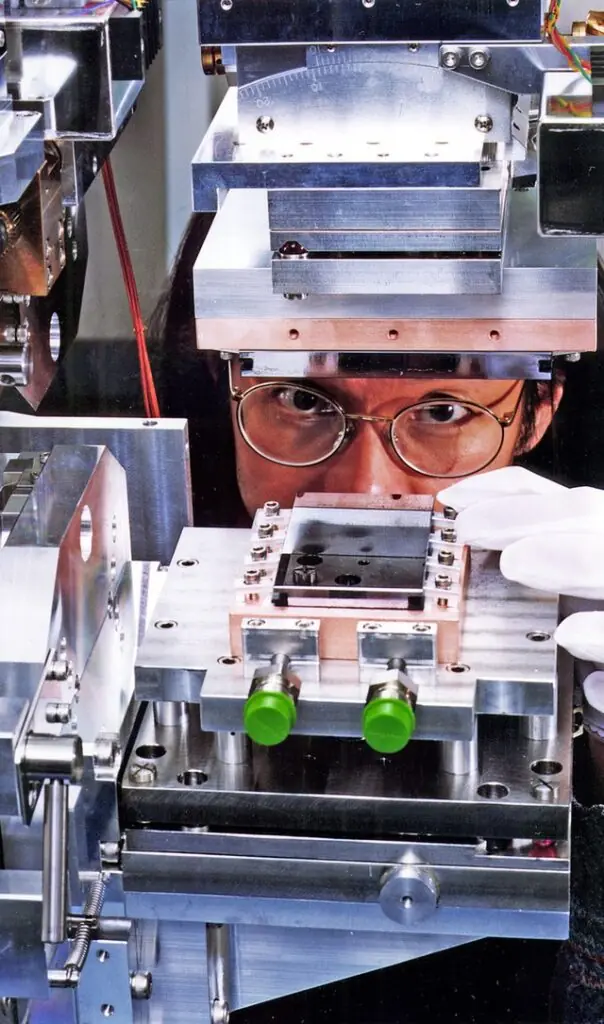

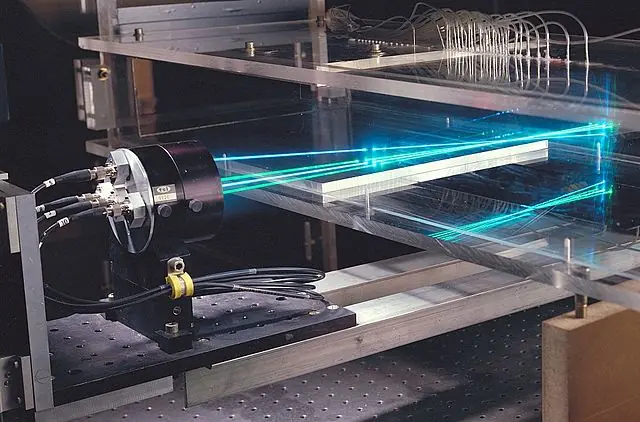

Fiber coupled lasers are a type of laser system where a laser beam is coupled into an optical fiber to provide efficient power transmission and precise beam delivery. In fiber coupled lasers, a high-power laser beam is launched into a fiber optic cable to transmit power and control the beam’s direction. The coupling process involves precise alignment of the laser beam with the core of the fiber optic cable, which ensures that the laser beam is efficiently transferred to the fiber.

The optical fiber in a fiber coupled laser system is responsible for transmitting the beam from the laser source to the target. The fiber’s core is where the light is guided, and the cladding around the core is used to confine the light in the core. The core of the fiber and the laser source must be precisely aligned to ensure that the laser beam is efficiently coupled into the fiber. The diameter of the fiber’s core determines the amount of light that can be transmitted through the fiber. Therefore, fibers with larger cores can transmit more light and are suitable for high-power applications.

The collimator is another essential component of a fiber coupled laser system. It is used to adjust the beam’s direction and size to match the core of the optical fiber. The collimator is positioned between the laser source and the fiber’s end, and it can be adjusted to control the beam’s direction and focus. The collimator is critical in ensuring that the laser beam is launched into the fiber at the correct angle and position, allowing the maximum amount of light to be transmitted through the fiber.

Applications of Fiber Coupled Lasers

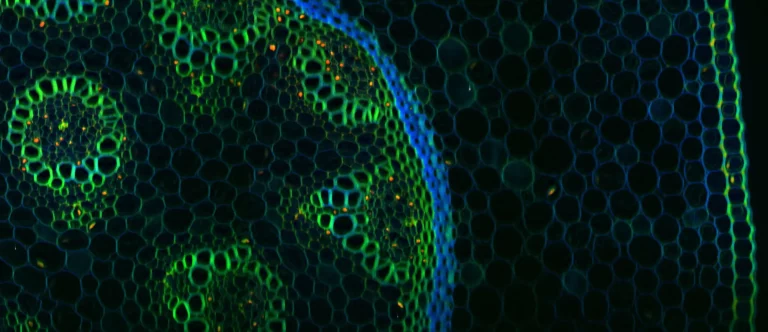

Fiber coupled lasers have been widely adopted in many industries due to their precision, high power, and efficient beam delivery. One of the primary applications of fiber coupled lasers is in the medical field, where they are used for diagnosis, therapy, and surgical procedures. For instance, in dentistry, fiber coupled lasers are used to perform delicate procedures such as removing tooth decay and shaping gum tissue. In ophthalmology, fiber coupled lasers are used to treat various eye conditions such as cataracts and glaucoma. The precision of fiber coupled lasers allows for high levels of accuracy during these procedures, reducing the risk of complications and improving patient outcomes.

Another significant application of fiber coupled lasers is in material processing. They are used in applications such as welding, cutting, and drilling. In the automotive industry, fiber coupled lasers are used for cutting and welding car components, while in the aerospace industry, they are used for drilling and cutting airplane parts. Fiber coupled lasers enable precise and efficient material processing, reducing material waste and increasing productivity.

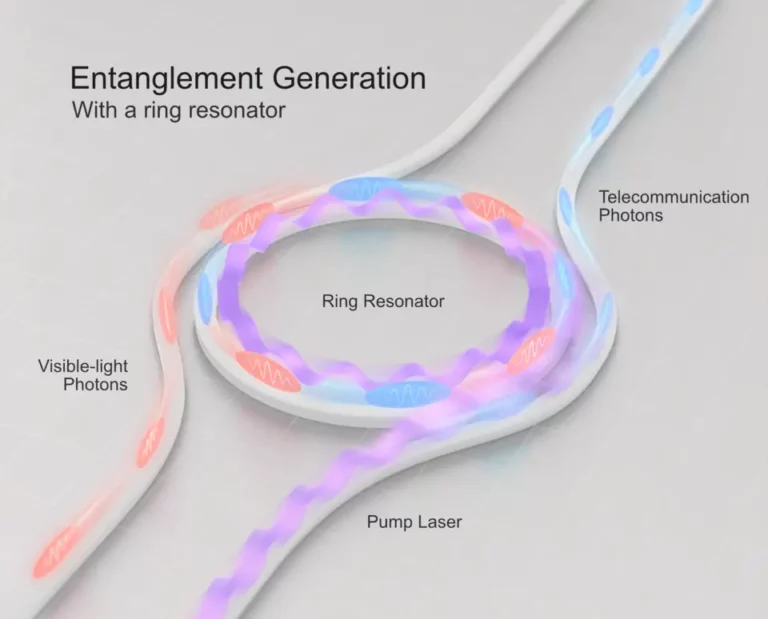

In the telecommunications industry, fiber coupled lasers are used in optical communication systems. Fiber optic cables provide a faster data transmission rate than traditional copper wires, and fiber coupled lasers play a crucial role in maintaining the integrity of these systems. They are also used in other industries such as spectroscopy, research, and development, and military applications.

Challenges in Fiber Coupled Lasers

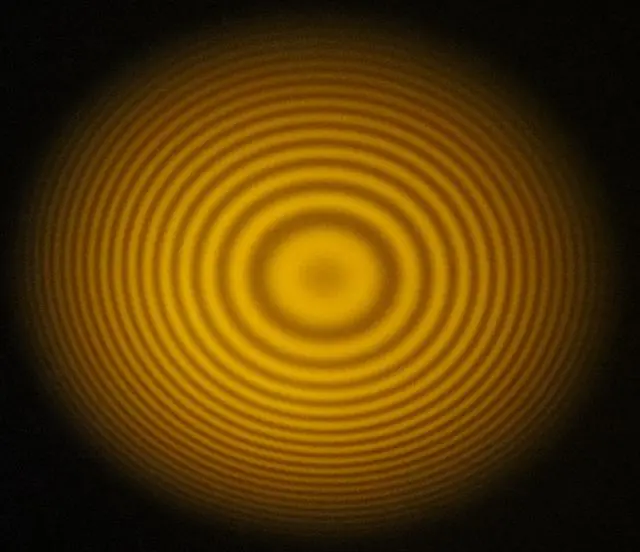

While fiber coupled lasers have revolutionized many industries, they also present significant challenges. One of the main challenges is maintaining the beam quality during the coupling process. Any imperfections in the beam can result in significant power losses, reducing the overall efficiency of the system. Therefore, ensuring a high coupling efficiency is essential for optimal laser performance.

Another significant challenge in fiber coupled lasers is power transmission. As the power output of lasers continues to increase, so does the need for efficient power transmission. The higher the power output, the more challenging it becomes to manage the heat generated by the laser, leading to thermal management challenges.

Beam shaping and beam quality are also important challenges in fiber coupled lasers. In applications where high levels of precision are required, such as in medical procedures or material processing, beam quality is crucial. Any deviations from the desired beam shape or quality can result in inaccurate or inefficient processes, affecting the overall outcome of the application.

To address these challenges, researchers are exploring new materials, manufacturing techniques, and innovative cooling systems. Advances in laser diode technology and optical fiber design are also contributing to improved beam quality and coupling efficiency. Additionally, modeling techniques and simulations are being developed to optimize the coupling process and improve laser performance.

Current Trends in Fiber Coupled Lasers: The Future is Bright

The future of fiber coupled lasers looks promising, with new trends and advancements in the field. Researchers are exploring new materials and manufacturing techniques to improve the efficiency and precision of fiber coupled lasers. There is also a growing interest in developing fiber coupled lasers for use in high power applications.

Fiber coupled lasers have significantly improved the efficiency and precision of various industrial applications. Advancements in the field have addressed challenges such as power transmission and beam quality, and have led to the development of more efficient and precise fiber coupled lasers. The potential for fiber coupled lasers is vast, with new trends and research leading to innovative applications that will shape the future of many industries.