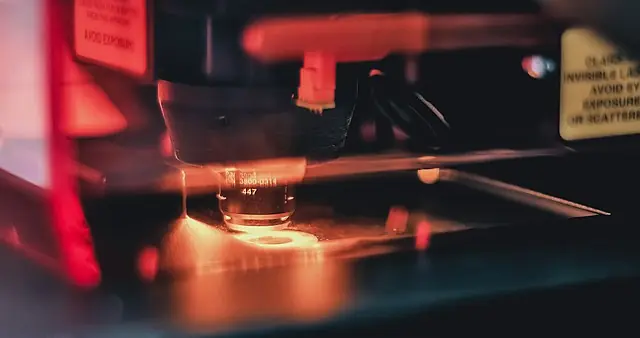

Exploring the Benefits and Limitations of Selective Laser Sintering of Metals and Ceramics

Selective Laser Sintering (SLS) is a 3D printing technology that has been used to produce parts from a variety of materials, including metals and ceramics.

Information about lasers in industrial uses including engraving, cutting, stereolithography, selective laser sintering, and more.

Selective Laser Sintering (SLS) is a 3D printing technology that has been used to produce parts from a variety of materials, including metals and ceramics.

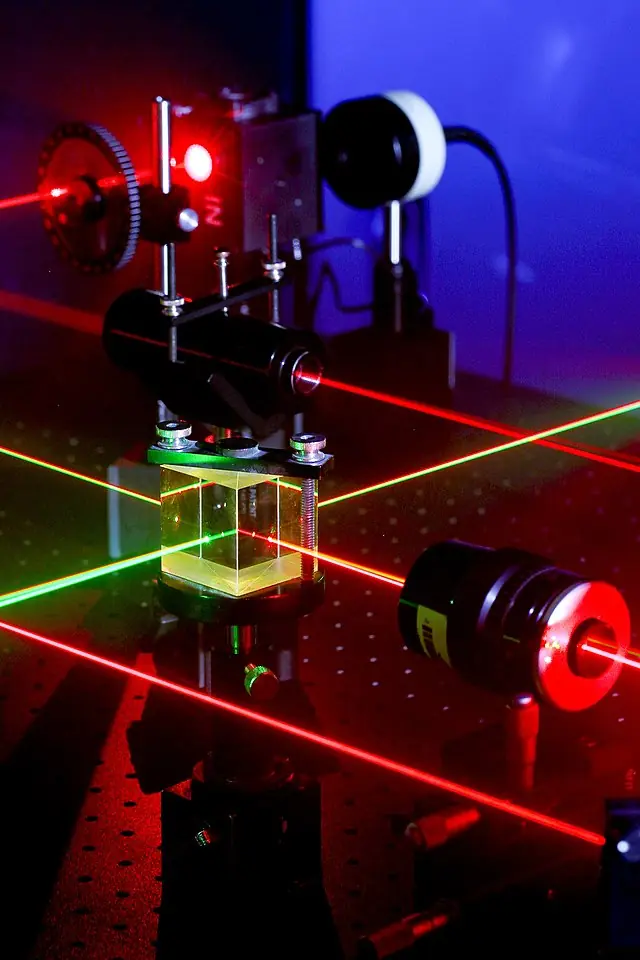

Polarizing beamsplitter cubes (PBSCs) and non-polarizing beamsplitter cubes (NPBSCs) are optical devices that are used to split an incoming light beam into two separate beams.

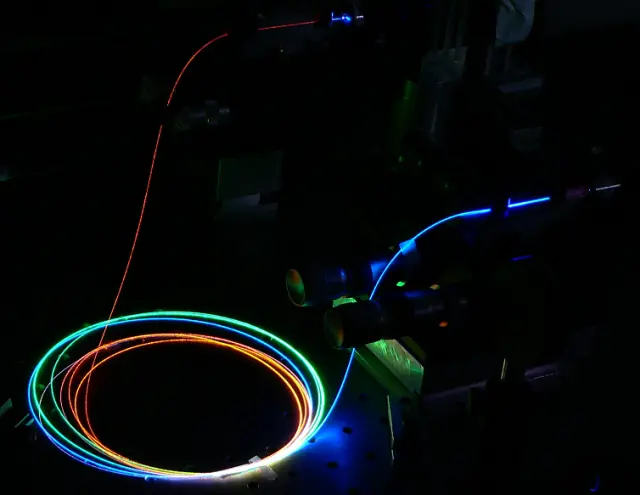

In this article, we will delve into the world of fiber lasers, exploring the different types and their applications.

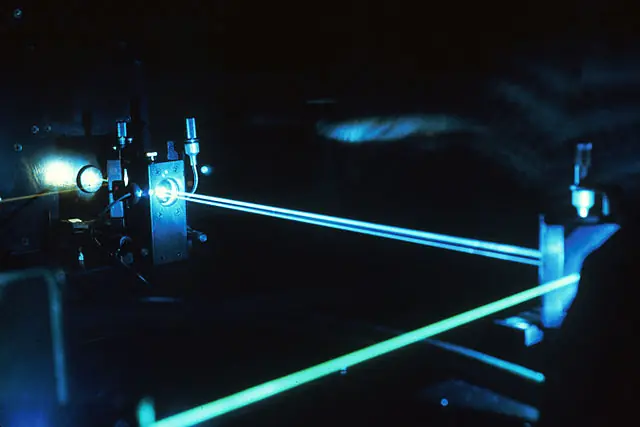

These devices use the principles of physics to measure distances with exceptional accuracy and precision. But, how do they work, and what types are available in the market?

A dye laser is a laser that uses an organic dye as its gain medium. The dye is usually dissolved in a solvent, such as ethanol, and is pumped by a laser beam to produce laser action. The wavelength of the laser light is determined by the properties of the dye, and can be tuned by changing the dye.

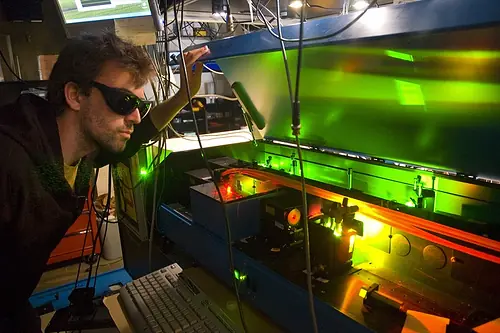

Lasers have been used in industrial settings for decades, but their use has been largely limited to cutting and welding applications. However, recent advances in laser technology are beginning to open up new possibilities for using lasers in a wide range of material processing applications.

In this article, we will explore laser shock peening, its applications, benefits, limitations, and future prospects.

A femtosecond laser is a type of laser that generates extremely short pulses of light, with a duration measured in femtoseconds (1 femtosecond is equal to 10^-15 seconds).

Argon-ion lasers are a type of gas laser that uses an argon plasma to produce light. The first argon-ion laser was built in 1964 by William Bridges at the Hughes Research Laboratories.

Laser cleaning is a process that utilizes a high-energy beam of light to remove contaminants, such as dirt, grime, rust, and paint, from a surface without causing any damage to the underlying material.

End of content

End of content