Femtosecond Laser Machining: A Revolution in Precision Manufacturing

Femtosecond laser machining has emerged as a revolutionary force in precision manufacturing and material processing. Capable of achieving unprecedented accuracy and resolution, this advanced technology has opened up new possibilities in various industries, from microelectronics to biomedical engineering. In this comprehensive article, we will delve into the historical background of femtosecond laser machining, discuss its fundamental concepts and principles, explore current research and advancements, examine its applications and implications, and consider the future prospects and challenges in this rapidly evolving field.

Historical Background

Research and knowledge related to femtosecond laser machining have developed over several decades, beginning with the invention of the laser in the early 1960s. Since then, laser technology has evolved significantly, with ultrashort pulse lasers making their debut in the 1980s. The term “femtosecond” refers to the duration of these ultrafast laser pulses, which last only 10^-15 seconds.

Key milestones in this field include the development of chirped pulse amplification by Gérard Mourou and Donna Strickland in the late 1980s, a breakthrough that earned them the 2018 Nobel Prize in Physics. This discovery enabled the generation of ultra-high peak power laser pulses without damaging the amplification materials, paving the way for femtosecond laser machining.

Fundamental Concepts and Principles of Femtosecond Laser Machining

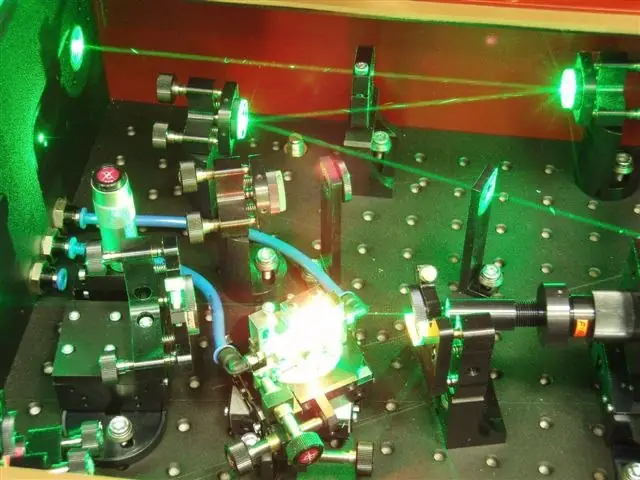

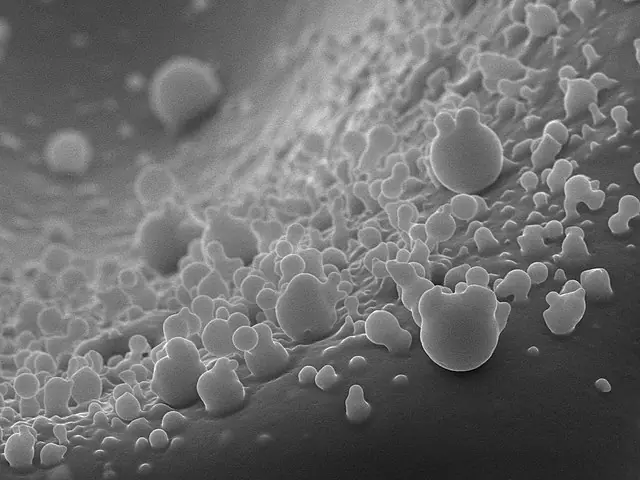

The core concepts behind femtosecond laser machining involve the use of ultrafast laser pulses to selectively remove material from a target substrate. This occurs through a process known as nonlinear multiphoton absorption, wherein the material absorbs multiple photons simultaneously. The absorbed energy causes localized melting or vaporization of the material, resulting in precise ablation.

One key advantage is the minimal heat affected zone (HAZ) around the area being machined. Because the pulses are so short, there is little time for heat to spread to the surrounding material, minimizing thermal damage. This allows for the processing of heat-sensitive materials and enables the creation of complex structures with minimal collateral damage.

Current Femtosecond Laser Research and Advancements

Recent research in femtosecond laser machining has focused on refining the technology and expanding its capabilities. This includes the development of new laser sources, such as fiber lasers, which offer improved energy efficiency and more compact designs. Additionally, researchers are investigating ways to optimize laser parameters and improve beam shaping techniques for enhanced precision and control.

These advancements have significant implications for various industries, as they enable the production of increasingly intricate and sophisticated components. For example, in microelectronics, femtosecond laser machining allows for the fabrication of smaller and more densely packed integrated circuits, which can lead to faster and more powerful electronic devices.

Applications of Femtosecond Laser Machining

Femtosecond laser machining has a wide array of applications across multiple industries, driven by its remarkable precision, minimal heat affected zone, and ability to process a variety of materials. In this expanded section, we delve into several key applications and describe their significance.

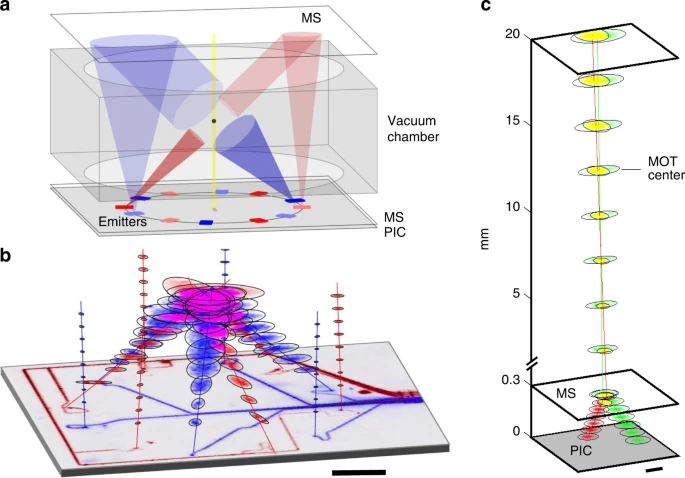

- Microelectronics: Femtosecond laser machining plays a critical role in the fabrication of microelectronic devices, such as integrated circuits and microelectromechanical systems (MEMS). Its precision enables the production of high-density, miniaturized components, which can lead to faster, more efficient, and powerful electronic devices. Specific applications include cutting and drilling of printed circuit boards, structuring of thin-film solar cells, and trimming of micro-scale resistors.

- Biomedical Engineering: In the biomedical field, femtosecond lasers are employed for various applications, including precision surgical procedures, tissue engineering, and medical implant fabrication. For example, femtosecond laser-assisted in-situ keratomileusis (LASIK) surgery is used to correct vision by reshaping the cornea with minimal damage to surrounding tissue. Additionally, the technology is utilized in the production of drug delivery systems, such as microneedles and stents, as well as the creation of custom-fit implants like dental crowns and hearing aids.

- Aerospace and Automotive Industries: Femtosecond laser machining is valuable in the aerospace and automotive sectors for the production of lightweight, high-strength components. It enables the precise structuring and drilling of advanced materials, such as carbon fiber composites and high-performance alloys. This technology helps improve fuel efficiency and overall performance in aircraft and vehicles by reducing weight without compromising structural integrity.

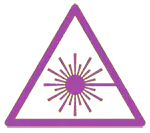

- Photonics and Optoelectronics: In the field of photonics and optoelectronics, femtosecond laser machining is used for the fabrication of optical components and devices, such as waveguides, gratings, and micro-optical elements. These components are essential for a variety of applications, including telecommunications, sensing, and imaging. The high precision of femtosecond lasers allows for the production of complex optical structures with superior performance characteristics.

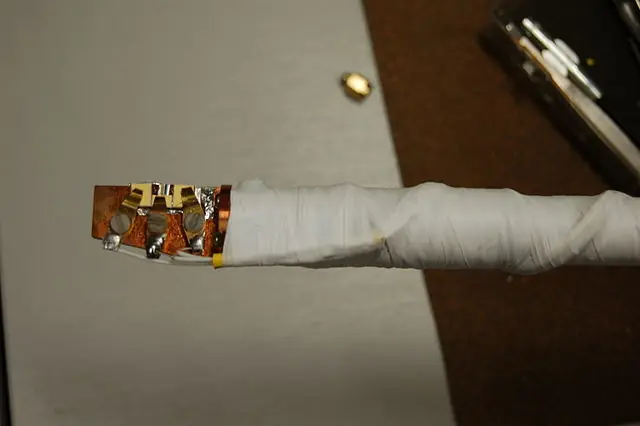

- Nanotechnology and Material Science: Femtosecond laser machining is an essential tool in nanotechnology and material science research, allowing for the creation of nanostructures and the manipulation of materials at the atomic scale. Examples include the production of nanowires, nanopillars, and quantum dots, which have applications in areas such as solar energy harvesting, sensing, and quantum computing.

- Artwork and Cultural Heritage Preservation: The precision and non-destructive nature of femtosecond laser machining make it suitable for artwork restoration and cultural heritage preservation. The technology can be employed to remove unwanted surface layers, such as dirt, paint, or varnish, without damaging the underlying material. This helps maintain the integrity of valuable artifacts while preserving their original appearance.

- Watchmaking and Jewelry Industry: Femtosecond laser machining is increasingly used in the watchmaking and jewelry industries for tasks such as engraving, cutting, and polishing of intricate designs. The technology enables the creation of highly detailed, precise, and durable components, contributing to the production of luxury timepieces and jewelry with exceptional quality and craftsmanship.

These applications demonstrate the versatility and potential across a range of industries. As the technology continues to evolve, we can expect to see even more innovative and transformative applications emerge, further solidifying its importance in modern manufacturing and research.

Future Prospects and Challenges

The future of femtosecond laser machining is expected to witness continued advancements in laser technology, beam shaping, and processing techniques. Researchers will explore new materials and applications, pushing the boundaries of what is possible with this cutting-edge technology. In addition, the integration with other advanced manufacturing techniques, such as additive manufacturing, could lead to the development of novel hybrid processes with even greater capabilities.

However, the field also faces several challenges. One of the primary concerns is the need for further improvements in energy efficiency and cost-effectiveness, making femtosecond laser machining more accessible and affordable for a wider range of industries. Additionally, there is a need for standardized processes and guidelines to ensure consistent results, particularly as the technology becomes more widespread.

Conclusion

In summary, femtosecond laser machining is a revolutionary technology with the potential to transform precision manufacturing and material processing across diverse industries. Through its historical development, fundamental concepts, and ongoing research, this technology has demonstrated its ability to produce intricate components with high precision and minimal damage. As we continue to explore its applications, implications, and future prospects, femtosecond laser machining will undoubtedly play a crucial role in advancing science and technology. We encourage readers to further explore this fascinating field and consider its potential impact on the future of manufacturing and innovation.